ENGINEERED FOR HIGH-RISK CHEMICAL ENVIRONMENTS

R.MOR PROTECTIVE WEAR® GORE-TEX® Chemical Splash Protective Gear keeps workers safe, visible, and mobile—even in hazardous liquid environments. Lightweight, breathable, and built to last.

Shop By Categories

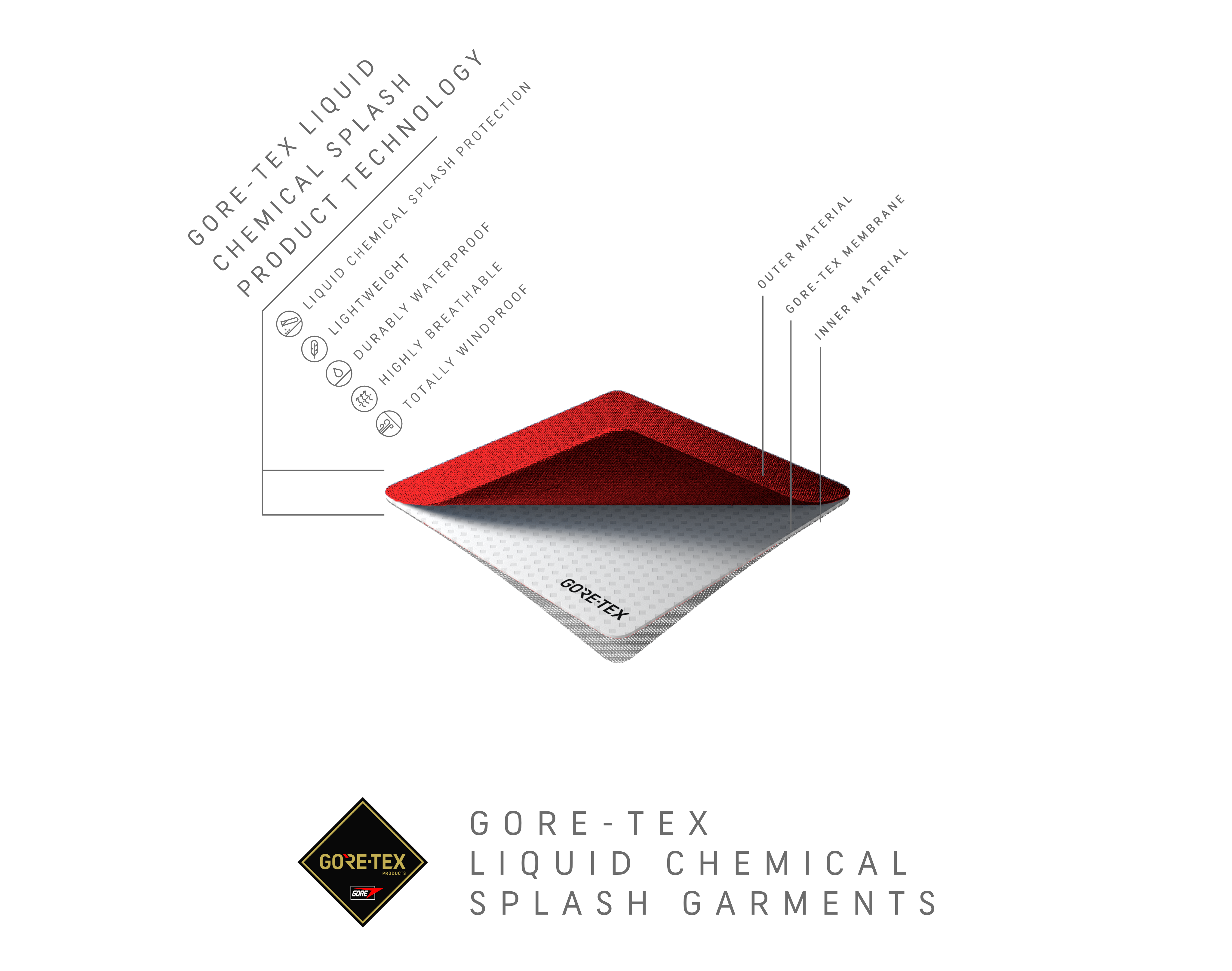

Our GORE-TEX® Chemical Splash and Multi-Hazard GORE-TEX PYRAD® garments are engineered for environments where liquid chemical exposure is a concern—but vapor exposure is minimal. These reusable garments provide reliable splash and multi-hazard protection while remaining lightweight, breathable, and comfortable for extended wear.

From waterproof and windproof protection to multi-functional chemical and arc-rated defense, Lac-Mac’s garments are trusted in industries that require uncompromising safety and worker comfort.

Red Texturized Polyester

Multi-Hazard GORE-TEX PYRAD®

Insulated NOMEX® Outer Shell (Navy)

Hi-Vis Orange Outer Shell

-

Trusted materials

Each garment is seam-sealed with GORE-SEAM® Tape and stitched with GORE® Tenara® Thread for maximum chemical durability.

-

Certified security

Meets NFPA 1990 performance standards, verified through UL testing and third-party certification.

-

Lightweight breathability

Technical GORE® fabrics allow heat and moisture to escape—keeping workers safer and more comfortable for longer wear.

-

Cost effectiveness & sustainability

Our garments are washable and reusable, reducing long-term PPE costs and supporting environmental goals.

Certified Protection Against Chemical and Industrial Hazards

-

WWW.NFPA.ORG

This standard provides requirements for protection for emergency responders against adverse liquid‑splash environments during hazardous materials emergency incidents.

Provisions specify design, performance, certification, and documentation requirements; test methods for new liquid splash‑protective ensembles and liquid splash‑protective clothing. Additional optional criteria for escape protection only from chemical flash fires encountered during hazardous materials incidents are also provided.

-

Standard Performance Specification for Flame Resistant and Electric Arc Rated Protective Clothing Worn by Workers Exposed to Flames and Electric ArcsWWW.ASTM.ORG

-

Standard Specification for Flame-Resistant Rainwear for Protection Against Flame HazardsWWW.ASTM.ORG

-

Standard Specification for Arc and Flame Resistant Rainwear.WWW.ASTM.ORG

-

ANSI/ISEA 107‑2015 provides performance requirements for conspicuous materials to be used in HVSA and specifies minimum amounts of background, retroreflective and combined‑performance materials, colors and placement of materials for garments, supplemental items and accessory items used to enhance the visibility and safety of workers. The 2015 edition continues to present three performance classes of garments based on the amount of visible materials and design attributes incorporated into the final configuration and now identifies garment types based on expected use settings and work activities being performed. These are designated as off‑road (type O), roadway and temporary traffic control (type R), or public safety activities (type P).WEBSTORE.ANSI.ORG

-

Z96‑15 - High‑visibility safety apparel: In working environments where lighting can range from well illuminated to low‑light or dark, visibility of the worker can mean the difference between safety and workplace injuries, even fatalities. The third edition of CSA Z96 High‑Visibility Safety Apparel focuses on the performance of retroreflective and background materials and their visibility under both well illuminated and darker working environments. It incorporates advice on selection, use, and care of high‑visibility safety material and includes recommendations for hazard assessments.WWW.OSHA.GOV